Project Location: Las Vegas, NV

Overview: Bi-directional tests are typically performed on dedicated foundation elements, but not always. The test can be performed on a production element, if provisions are made to grout the expanded jacks and the annular space around them afterwards, and the design does not require continuous reinforcing steel below the load test assembly depth.

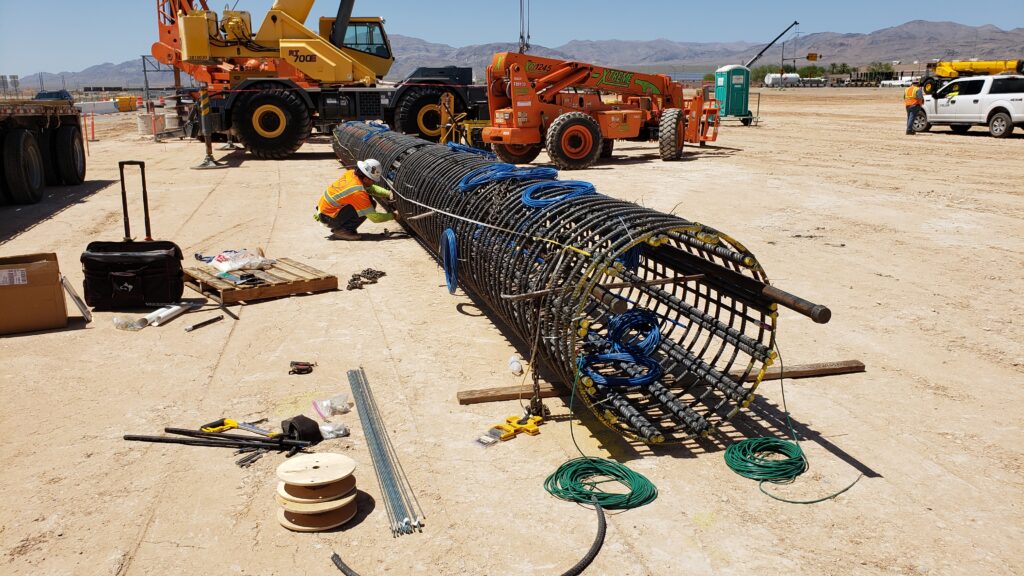

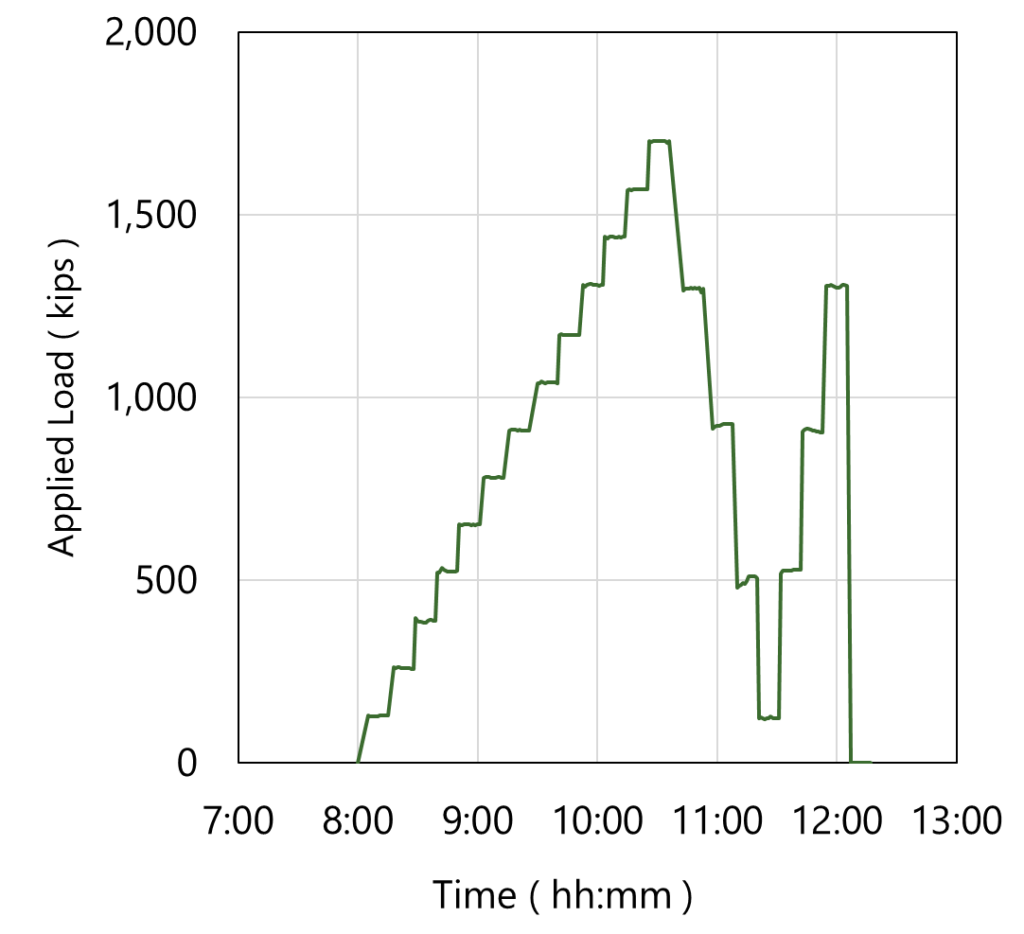

This was the case for a recent test performed for the Nevada DOT on their 215 over I-15 flyover site, located northeast of downtown Las Vegas. The test element was a 4-foot diameter, 57-foot deep drilled shaft at a production location. As typical with production tests, the load schedule included a primary cycle to maximum test load (1,700 kips in this case) and a secondary cycle to 1,300 kips (double design load) to demonstrate that the drilled shaft’s shear capacity was not permanently weakened by the test.

The drilled shaft contractor was Keller North America, with our good friends at GEO-Instruments assisting with instrumentation and testing. The test objectives were all met, with the resulting data indicating the shaft would only settle ⅛ inch at a top load of 2,500 kips and could be used as part of the structure’s foundation.